How to Make LED Outdoor Light Strips Waterproof

Published: Last Updated: Estimated Reading time: 6 minsWhat would happen if you directly install LED light strips without any water protection and solid object protection outdoors?

Nothing may happen briefly, but soon or slowly, when it turns to rain, LED will inflow water and lead to a short circuit.

So, what allows LED strip lights to bring light for humans outdoors?

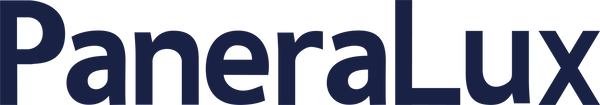

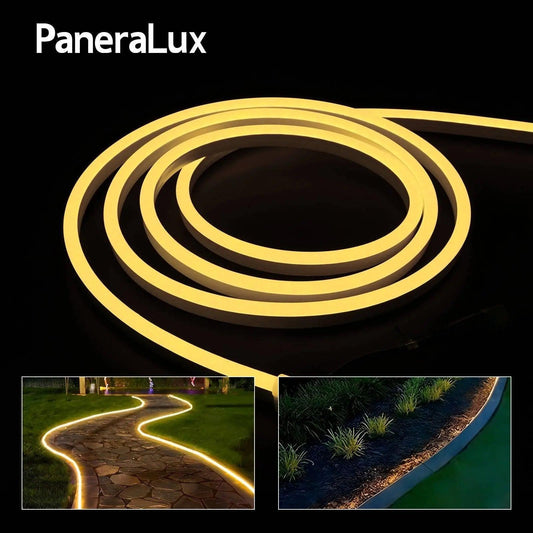

Explore the waterproof design to LED strip lights for pools, and of course it’s the same with other outdoor LED lights, like lights for pool illumination, water fountain, and more applications.

Table of Contents:

1. Suitable Types of Waterproof LED Strip Lights Outdoors

Before know how to waterproof led strip lights, we have to know what waterproof level of led lights is suitable for outside use:

The most frequent types of outdoor led strip lights are IP65, IP67, IP68.

We last posted a blog of outdoor led strips to help you Choose Waterproof LED Strip Lights for Outdoor Use, see more details in 3 Steps to Choose Waterproof LED Strip Lights for Outdoor Use – PaneraLux.

2. 5 Common Waterproof Materials to Outdoor Light Strips

What could be used to waterproof led strip lights for pools? It has to be a super clear chemical so the light can shine through.

And there are five that meet the requirements: Silicone, PVC, PU(Polyurethane), PO(Polyolefin), Epoxy resin.

Silicon

Silicon is a popular material for waterproof LED strips due to its high resistance to water and other liquids. It is flexible and can easily conform to various shapes and sizes, making it ideal for use in a wide range of applications.

PVC

PVC (Polyvinyl Chloride) is another popular material used for waterproof LED strip lights. It is also flexible and easy to shape, making it ideal for use in curved or uneven surfaces. PVC is also resistant to water and other liquids, making it a popular choice for outdoor use.

PU

PU (Polyurethane) including PU glue and TPU(Thermoplastic Polyurethane), can be used as a waterproof shell for LED light strips. PU glue provides strong bonding and weather resistance, and TPU offers flexibility and abrasion resistance. Both can effectively seal the LED strip from moisture and others.

PO

PO (Polyolefin) usually be used as clear heat shrink tubing, and let heat shrink sleeve flexible and flame retardant. When heat is applied, the tubing shrinks and conforms tightly around the LED strip, creating a protective barrier that seals out moisture and other contaminants.

Epoxy Resin

Epoxy Resin is a popular material used to encapsulate LED strips for waterproofing. It is made by two parts(resin and hardener) and mixed together and then applied to the LED strip. Once cured, epoxy provides excellent water resistance and durability.

|

Item |

Silicone |

PVC |

PU glue |

PO |

Epoxy Resin |

|

Cost |

Highest |

Low |

High |

Low |

Low |

|

Temperature Resistance |

-40-220℃ Performance remained stable |

-25-60℃ Brittle in low temperature |

-40-80℃ Performance remained stable |

-55~125℃ Performance remained stable |

0-60℃ Harden in low temperature |

|

Heat Conductivity |

High |

Low |

High |

High |

Low |

|

Yellowing |

No 3 Years |

1-2 years |

No |

No 3-5 years |

Obvious after half a year |

|

Toxicity |

No |

High after heated, bad smell |

High, bad smell |

No |

Low |

|

Light Transmission Rate |

96% |

50-60% |

95% |

90% |

92% |

3. 4 Common Outdoor LED Strip Light Waterproofing Methods

Coating (for IP52)

- IP Rating: Typically achieves IP52 (protection against dust and dripping water).

- Advantages:

- Simple application process.

- Maintains flexibility of the LED strip.

- Considerations:

- Coating thickness and quality affect IP rating.

- May require reapplication over time.

Heat Shrink Tube (for IP65)

- IP Rating: Achieves IP65 (dust-tight and protected against water jets).

- Advantages:

- Provides a snug fit and good protection.

- Relatively easy and quick installation.

- Considerations:

- Requires careful sizing and sealing at ends.

- Limited flexibility after installation.

Tube (for IP67)

- IP Rating: Achieves IP67 (dust-tight and protected against immersion up to 1 meter).

- Advantages:

- Provides robust protection against moisture and dust.

- LED strips can be replaced or adjusted if needed.

- Considerations:

- Requires careful sealing to maintain IP rating.

- Can be bulkier compared to other methods.

Full Encased (for IP67/IP68)

- IP Rating: Achieves IP67 or IP68 (dust-tight and protected against continuous immersion).

- Advantages:

- Maximum protection against water, dust damage.

- Allows for flexibility in LED strip length and replacement.

- Considerations:

- More complex installation compared to other methods.

- Provides a durable, long-lasting solution for outdoor environments.

And now, led light strips outdoors which can be used outdoors are completed.

Hope it's helpful to you to know more about led strips.

And you can get ideas about led strips for outdoor use.

Elevate your outdoor experience with PaneraLux pool and outdoor LED strips and make every moment outdoors unforgettable.

For expert advice and assistance in choosing the perfect LED strip lights for your outdoor space, feel free to reach out to our team. Email or click the icon in the bottom right corner, chat with us and you can get professional advice soon.

These articles might be of interest to you:

Interested in how to waterproof led strip lights?

Worried about led lights fire hazard? Are led lights flammable?

Don’t know how to change pool lights for lux pool or how to install pool lights?

Want to know how to wire pool lights and outdoor lights?

Confused about the swimming pool light voltage? Hesitate between choosing a12v vs 120v pool light?

Showing effect videos of pool edge lighting and garden led strip:

Related data resource:

PVC temperature resistance: Picking the Right Material for Your LED Strip Lights Project - LED Controller Manufacturer, Supplier, Factory

PO temperature resistance: Heat shrink tube Φ8 for 10mm LED strip • Temperature ranges -55℃~125℃ • 1 Meter lenghts

Silicone temperature resistance: Advantages and disadvantages of PVC neon strips and silicone neon strips

Epoxy resin temperature resistance: Review of thermal conductivity in epoxy thermosets and composites: Mechanisms, parameters, and filler influences - Science Direct

PO temperature resistance: Solids, Liquids and Gases - Thermal Conductivities

Yellowing and Light transmission rate: PVC, Silicone, PU glue, three types material of LED Neon Strip-Product Knowledge - Yuchen Optoelectronic LED Lighting Solution Provider-Yuchen Optoelectronic LED Lighting Solution Provider